Series: HZS Series

Classification Concrete Mixing Plant

Contact information: RTZK2003@163.com

Series: HZS Series

Classification Concrete Mixing Plant

Contact information: RTZK2003@163.com

| Parameter | Unit | HZS60 | HZS90 | HZS120 | HZS180 | HZS240 | HZS270 |

| Theoretical productivity | ㎥/h | 60 | 90 | 120 | 180 | 240 | 270 |

| Mixer model | / | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 | JS4500 |

| Mixer power | kW | 2x22 | 2x30 | 2x37 | 2x55 | 2x75 | 2x75 |

| Recycling period | S | 60 | 60 | 60 | 60 | 60 | 60 |

| Maximum aggregate, particle size | mm | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 |

| Capacity of powder silo | t | 2x100 | 4x100 | 4x100 | 4x150 | 4x200 | 4x300 |

| Batching station model | L | 1600 | 2400 | 3200 | 4800 | 6400 | 6400 |

| Belt conveyor capacity | t/h | 300 | 500 | 700 | 1000 | 1200 | 1200 |

| Capacity of aggregate silo | ㎥ | 3x10 | 4x15 | 4x20 | 4x25 | 4x30 | 4x30 |

| Material discharging height | m | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 |

| Installed power | kW | 120 | 150 | 190 | 240 | 310 | 310 |

| Maximum capacity of screw conveyor | t/h | 40 | 40 | 80 | 80 | 110 | 110 |

| Aggregate weighing range/accuracy | kg | 1500±2% | 2000±2% | 2000±2% | 3000±2% | 4000±2% | 4000±2% |

| Cement weighing range/accuracy | kg | 600±1% | 800±1% | 1200±1% | 1800±1% | 2400±1% | 2400±1% |

| Coal powder dosing range/accuracy | kg | 300±1% | 400±1% | 600±1% | 800±1% | 1000±1% | 1000±1% |

| Water dosing range/accuracy | kg | 400±1% | 500±1% | 600±1% | 800±1% | 1000±1% | 1000±1% |

| Addtive dosing range/accuracy | kg | 30±1% | 30±1% | 30±1% | 50±1% | 50±1% | 50±1% |

| Product overview |

HZS series concrete mixing plant is a new type of mixing plant independently developed by Runtianzhike based on the advantages and using experience of various abroad similar products . It uses a twin-horizontal shaft mixer equipped with an automatic control system composed of industrial control microcomputers and programmable controllers. This system can mix concrete with various ratios. The station has advantages such as reasonable structural design, safe and reliable operation, fast speed, and accurate calculation. It is an ideal production equipment for the usage of large and medium-sized construction projects, hydro-power highways, ports, bridges, airports, large prefabrication plants, and commercial concrete production plants.

|

| Product characteristics | |

The materials used throughout the station are solid, and the main building legs and beams are made of large-sized H-shaped steel, which is sturdy and durable, with a service life of more than 10 years. |

|

Modular design concept, smart & convenient; Waterway,circuit and gas circuit reserve quick connector can be seamless connected, to elevate installation efficiency, reduce installation difficulty. |

|

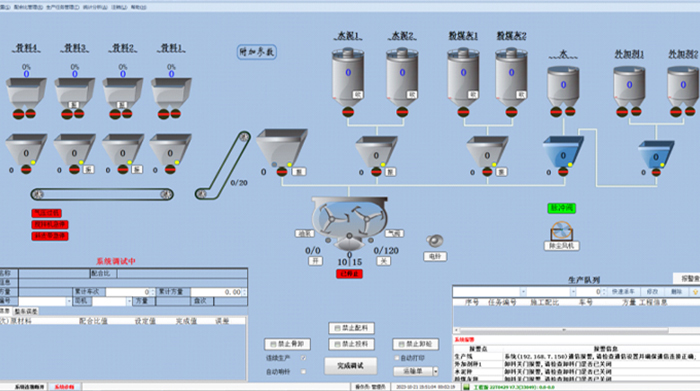

Centralized production control system keeps operation away from noise and dust environment enhance the image of the mixing station; Dual-control for dual-machine and single person for dual-control can both be realized reducing the production and management cost of about 60,000 yuan/year. |

|

High configuration, using well-known domestic & foreign brands of motors, reducers, electrical, and butterfly valve components.Ensuring the stability and durability of equipment operation, detailed configuration can be found in the configuration table. |

|

Optical container type structure, with modular design, the main building can be free from site packing, to achieve more convenient & fast installation. |

|

The high-speed railway station equipment adopts frame type weighing of cement + pulverized fuel ash + mineral powder to reduce the impact of building vibration on the dosing; Optional dual-screw conveyor and discharge butterfly valve automatic control, associated with pneumatic self-balancing technology to prevent the scale body from scale jumping or floating. |

|

Easy maintenance and operation, intelligent design in multiple locations, automatic lubrication, automatic alarm, reducing the difficulty of maintenance; During the production process, there is a system with fully automatic batching, automatic operation, and real-time data monitoring, making it easy to operate while ensuring accuracy. |

|

INTRODUCTION TO THE FUNCTIONAL MODULES OF THE BUCKETLIFTING TYPE CONCRETE MIXING PLANT |

|

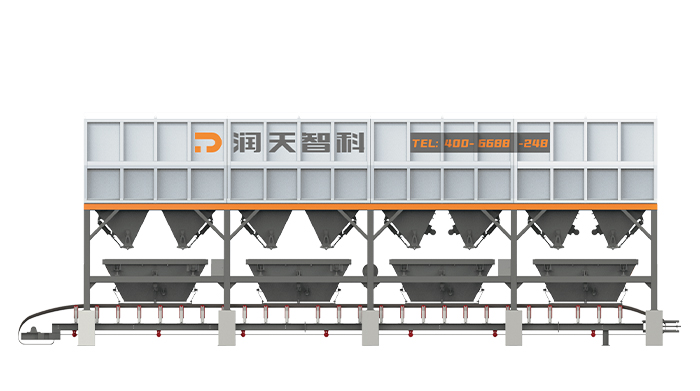

1 Batching system

Large size enclosure with a large amount of material storage;

Internal vibration type arch breaking device, smooth discharging; Double opening material door, material does not deviate; The rack adopts large-sized thick walled square tubes, with a solid structure. |

|

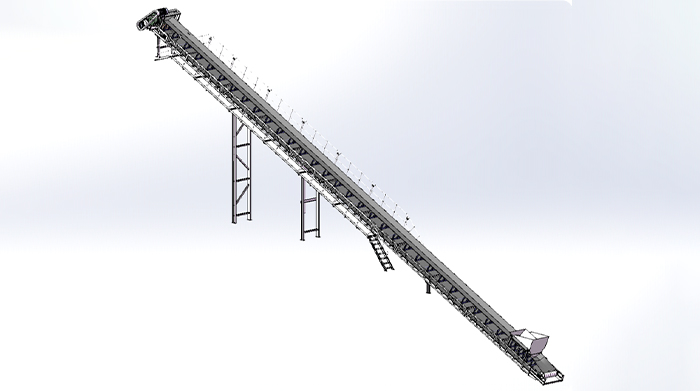

2 Belt conveying system The belt conveyor adopts a large-sized truss structure, which is stable and reliable; Flat belts, herringbone belts, and groove belts can be selected according to the size of the site; The driving mechanism is driven by a disc reducer and pulley, which has good stability; Dedicated belts and rollers are more durable. |

|

3 Unloading system Large angle discharge hopper smooth discharge Built in NM400 wear-resistant lining plate, with a long service life; Optional temporary storage hopper for higher efficiency. |

|

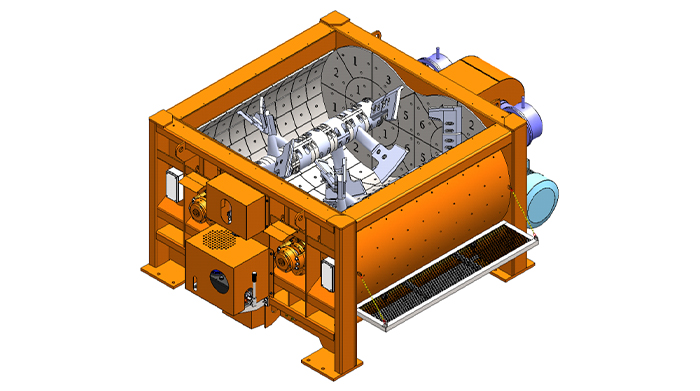

4 Mixing system

Independently developed mixing machine for more uniform mixing; Adopting high chromium alloy castings, with a long service life; The driving motor has high & strong power refusing mixer jamming; The optimized design of the water spraying pipeline ensures faster and more uniform drainage, while also preventing shaft sticking |

|

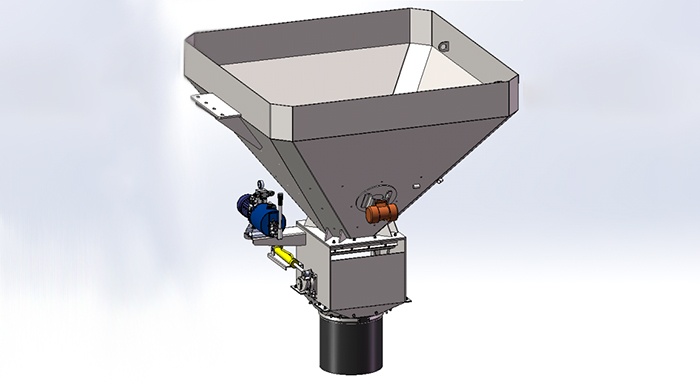

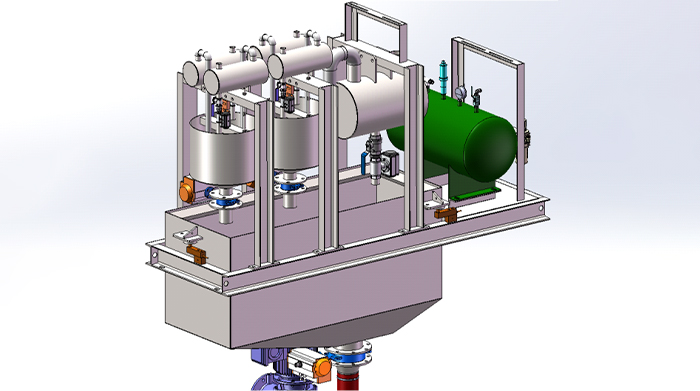

5 Dosing system Adopt rough&accurate dosing to all material, to achieve high accuracy; Each weighing hopper has an adaptive intelligent weighing function, the more to be used, the more accurate it will be. scale bucket has a large capacity and is suitable for more proportioning requirements. |

|

TEL: +86-4006688248

WORK: 8:00-18:00