INTRODUCTION

Series: HZS120TX

Classification Concrete Mixing Plant

Contact information: RTZK2003@163.com

Series: HZS120TX

Classification Concrete Mixing Plant

Contact information: RTZK2003@163.com

| Parameter | Unit | HZS60TX | HZS90TX | HZS120TX | HZS180TX |

| Theoretical productivity | ㎥/h | 60 | 90 | 120 | 180 |

| Model of mixer | / | JS1000 | JS1500 | JS2000 | JS3000 |

| Power of mixer | kW | 2x22 | 2x30 | 2x37 | 2x55 |

| Recycling period | S | 60 | 60 | 60 | 60 |

| Mixer | L | 1000 | 1500 | 2000 | 3000 |

| Max size of aggregate | mm | ≤80 | ≤80 | ≤80 | ≤80 |

| Capacity of powder silo | t | 2x100 | 3x100 | 4x100 | 4x150 |

| Batching capacity of he batching station | L | 1600 | 2400 | 3200 | 4800 |

| Capacity of aggregate silo | ㎥ | 3x10 | 4x15 | 4x20 | 4x25 |

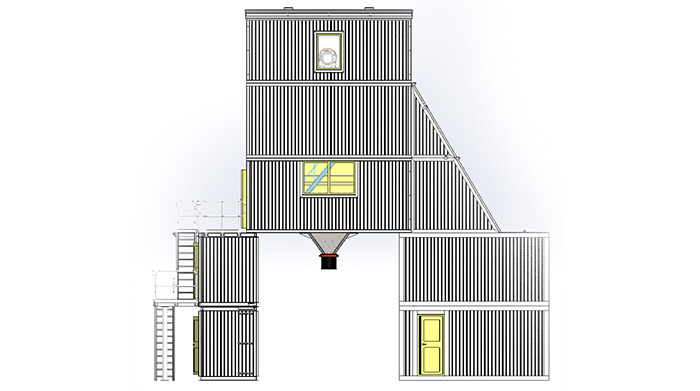

| Material discharging height | m | 4.2 | 4.2 | 4.2 | 4.2 |

| Iinstalled power | kW | 120 | 150 | 190 | 240 |

| Maximum capacity of screw conveyor | t/h | 40 | 40 | 80 | 80 |

| Aggregate weighing range/accuracy | kg | 1500±2% | 2000±2% | 2000±2% | 3000±2% |

| Cement weighing range/accuracy | kg | 600±1% | 800±1% | 1200±1% | 1800±1% |

| Coa powder dosing range/accuracy | kg | 300±1% | 400±1% | 600±1% | 800±1% |

| Water dosing range/accuracy | kg | 400±1% | 500±1% | 600±1% | 800±1% |

| Addtive dosing range/accuracy | kg | 30±1% | 30±1% | 30±1% | 50±1% |

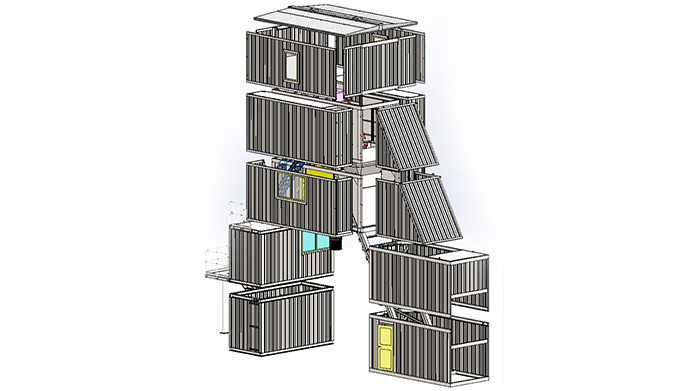

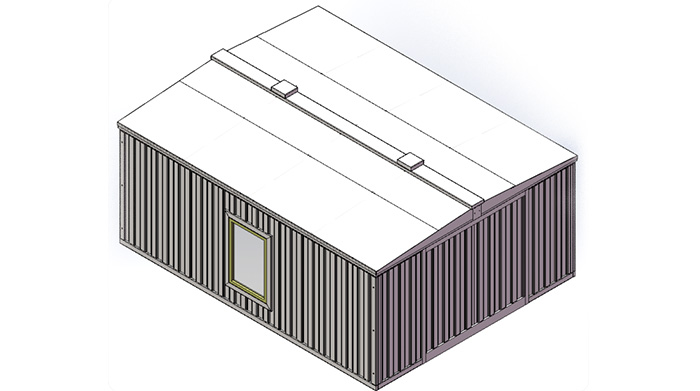

| Product overview |

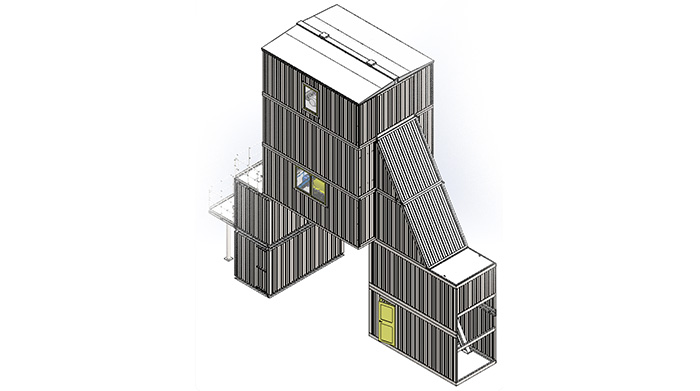

| Runtian Bucket-lifting Container Concrete Mixing Plant is a brand new product created based on the modular design concept of the existing product. In addition to the characteristics of the original bucket-lifting type mixing plant, it also has the characteristics of fast installation & relocation, high-end and atmospheric appearance, and is wisely used in the construction of highways, railways, municipal, and urban projects. |

| Product characteristics | |

| 1 Quick installation and relocation: The components are installed using a “block building” method; The disassembly and assembly time of the entire main building does not exceed half a day, which greatly improving installation efficiency and creating higher economic benefits. |

|

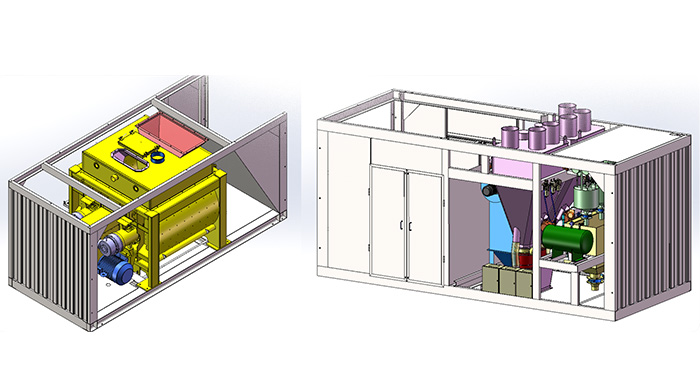

| 2 Integrated design: Each system module is reasonably distributed within each container and standardized production. |

|

| 3 Compact structure: Used in conjunction with a bucket, it occupies a small area and has high and utilization efficiency. |

|

| 4 Green and environmentally friendly: The integrated internal design greatly reduces the impact of dust, vibration, and noise on the surrounding environment, making it more environmentally friendly. |

|

| 5 Safe and stable: It adopts steel plate pressure welding packaging without the need for external sealing, and there is no need for external high-altitude operations. |

|

| 6 High transportation efficiency: There is no increase in transportation vehicles due to the use of frame structures, which is the same as the vehicles required for traditional mixing plants. |

|

TEL: +86-4006688248

WORK: 8:00-18:00