INTRODUCTION

Series: WDB series

Classification Stabilized Soil Mixing Plant

Contact information: RTZK2003@163.com

Series: WDB series

Classification Stabilized Soil Mixing Plant

Contact information: RTZK2003@163.com

| Parameter | Unit | WDB500G | WDB600G | WDB700G | WDB800G | WDB1000G |

| Theoretical productivity | t/h | 500 | 600 | 700 | 800 | 1000 |

| Mixer power | kW | 2x37 | 2x45 | 2x55 | 2x55 | 2x75 |

| Volume of batching hopper | ㎥ | 12 | 12 | 15 | 15 | 15 |

| Quantity of batching hopper | / | 4 | 4 | 4 | 4 | 4 |

| Maximum aggregate particle size | mm | 60 | 60 | 60 | 60 | 60 |

| Finished product silo volume | ㎥ | 10 | 10 | 12 | 12 | 15 |

| Discharge height of finished product silo | m | 4.1 | 4.1 | 4.1 | 4.1 | 4.1 |

| Aggregate weighing range/accuracy | % | ±2 | ±2 | ±2 | ±2 | ±2 |

| Powder dosing range/accuracy | % | ±1 | ±1 | ±1 | ±1 | ±1 |

| Water dosing range/accuracy | % | ±1 | ±1 | ±1 | ±1 | ±1 |

| Overall power | kW | 190 | 210 | 230 | 240 | 280 |

| Apparent dimension | m | 45x15x20 | 45x15x20 | 45x15x20 | 48x15x20 | 52x15x20 |

| Product overview |

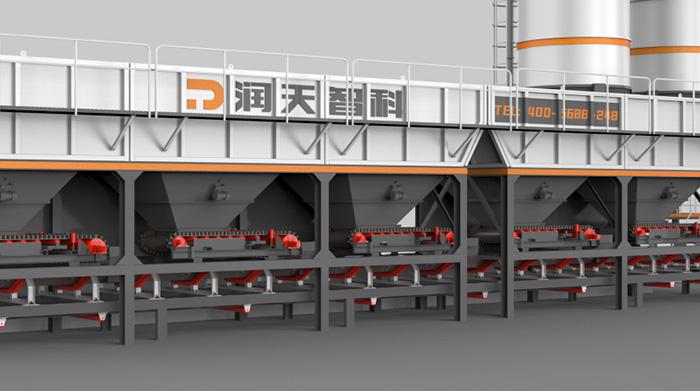

| Runtianzhike WDB series stabilized soil mixing plant are with obvious characteristics of foundation free, integrate, intelligent, easy to maintain and Eco-friendly etc have been widely used in railway, highway, bridge, municipal and other projects. |

| Product characteristics | |

| 1 Foundation-free design without pre-embedding greatly reduces the cost of foundation construction. Each component adopts integrated control, made of H-shaped steel as the column, firm and never deforms. The equipment can be installed after simple leveling of the site, and each major component can be hoisted within one day, saving installation time & cost. |

|

| 2 The materials used throughout the station are solid, and the legs of the batching machine and finished product silo are made of large-sized H-shaped steel,which is sturdy and durable, with a service life of more than 10 years. |

|

| 3 Unique cement transition silo and screw electronic scale dual dosing method,ensuring stable cement transportation, easy calibration, and high accuracy; All materials are controlled by frequency conversion, and the output can be adjusted at will: Powder conveying is fully sealed, pollution-free, and waste free: Adopting pneumatic self balancing technology the cement under the cement tank is smooth. |

|

| 4 High configuration, using well-known domestic & foreign brands of motors, reducers, electrical, and butterfly valve components. Ensuring the stability and durability of equipment operation, detailed configuration can be found in the configuration table. |

|

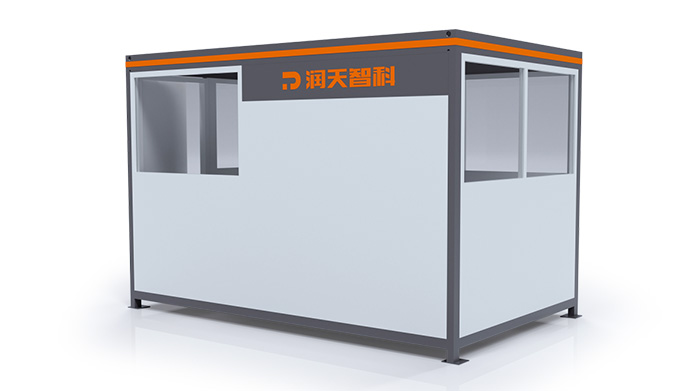

| 5 The fully sealed control room with air conditioning provides a wide field of view, providing a comfortable working environment for operators and reducing labor intensity. |

|

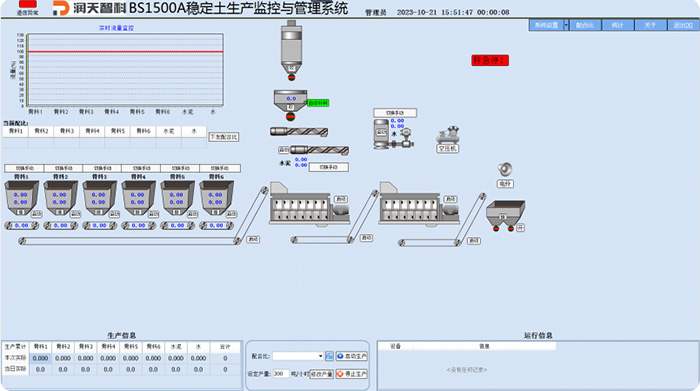

| 6 Intelligent work interface system. Adopting Access database,regularly recording production data supporting third-party development data upload; Regularly record production flow data and display it in the form of flow curves,making it easy to view historical production status and handle problems afterwards. It has an operation log function, making it easy to analyze and hold accountable afterwards. |

|

| 7 The large angle discharge hopper is combined with a vibration motor to ensure smooth discharge.Large volume finished product silo, with more storage capacity, making vehicle receiving materials more leisurely;Large size discharge door maximizing the use of carriage space. |

|

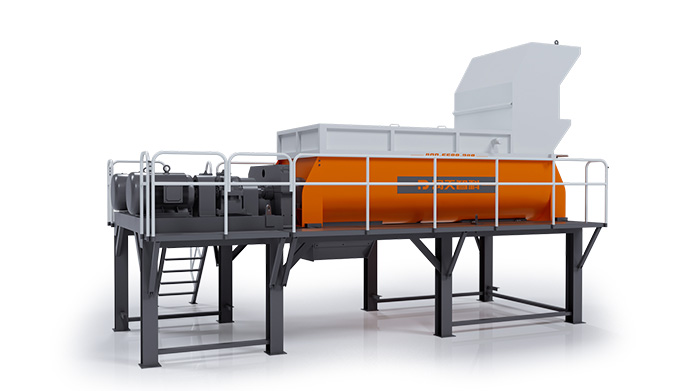

| 8 The mixer adopts a dual hard tooth reducer and dual motor drive mode, with low noise, sufficient power no material blockage. and no stuffiness: The extended mixing cylinder can make the materials boil and penetrate, to be mixed more evenly, secondary mixing can also be equipped. The shaft end bearing of the mixing cylinder is separated and sealed with three levers of sealing rings to prevent slurry leakage. |

|

| 9 There is no lining plate in the mixing cylinder, thus to reduce blade wear and problems such as clamping and hard scratching.Original streamline wear-resistant mixing knife arm and blade, no material sticking, easy to clean. |

|

| 10 The mixing system can be equipped with two-stage mixing, which can be in series or stacked forms to meet various customer needs. The secondary mixing machine has a higher power and strong power ensuring that it will not froze and the mixing effect is better and more uniform. |

|

| 11 Components such as the batching hopper, mixer, finished material silo, and inclined belt can all be equipped with environmentally friendly dust removal devices. The dust removal device adopts a system independently developed by Runtian, allowing different components of the equipment to use different methods under different working conditions, achieving ideal dust removal effects. |

|

TEL: +86-4006688248

WORK: 8:00-18:00