INTRODUCTION

Series: LCB series

Classification Stabilized Soil Mixing Plant

Contact information: RTZK2003@163.com

Series: LCB series

Classification Stabilized Soil Mixing Plant

Contact information: RTZK2003@163.com

| Parameter | Unit | LCB600G | LCB800G |

| Theoretical productivity | t/h | 600 | 800 |

| Mixer power | kW | 2x45+2x55 | 2x55+2x75 |

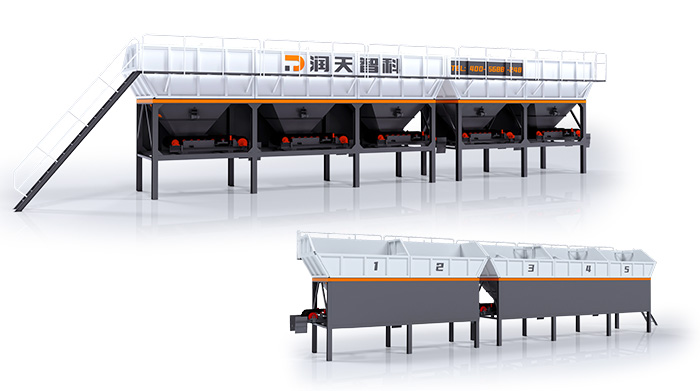

| Volume of batching hopper | ㎥ | 12 | 15 |

| Quantity of batching hopper | / | 4 | 5 |

| Maximum aggregate particle size | mm | 60 | 60 |

| Finished product silo volume | ㎥ | 10 | 12 |

| Discharge height of finished product silo | m | 4.1 | 4.1 |

| Aggregate weighing range/accuracy | % | ±2 | ±2 |

| Powder dosing range/accuracy | % | ±1 | ±1 |

| Water dosing range/accuracy | % | ±1 | ±1 |

| Overall power | kW | 380 | 450 |

| Apparent dimension | m | 62x15x20 | 65x15x20 |

| Product overview |

| The LCB series emulsified asphalt cold regeneration secondary mixing plant is a newly upgraded product recently introduced by Runtian. It is developed to meet the current market demands by further optimizing the existing cold regeneration stations. This product features dual-functionality for both water stability and cold regeneration applications. |

| Product characteristics | |

| 1 Compact Structure Modular design with a compact structure, requiring less space, convenient installation & relocation. |

|

| 2 One machine for dual use. In addition to being a cold regeneration mixing plant, it can also be used as a conventional stabilized soil mixing station, providing dual function to create greater economic benefits for customers. |

|

| 3 Accurate Dosing. Powder supply adopts dual-dosing of frequency converting screw + transmission bucket reduction scale technology. It dynamically displays instantaneous flow rates and accumulates total flow rates,dosing accuracy is controlled within 1%;The powder adopts secondary dosing with high accuracy; Water supply and emulsified asphalt system adopts intelligent electromagnetic flow meters and frequency-controlled speed regulation technology for accurate dosing and intuitive display. |

|

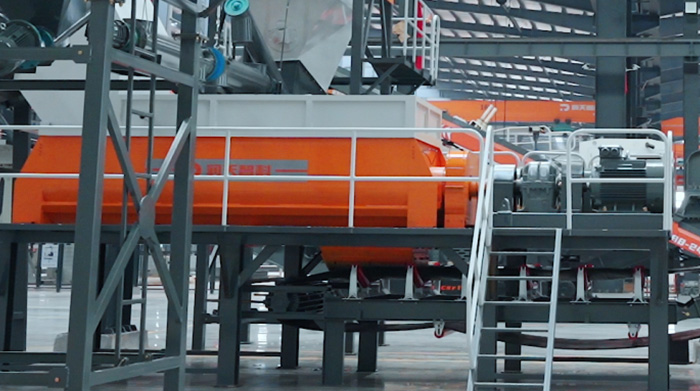

| 4 Independently developed mixing machine for more uniform mixing; Adopting high chromium alloy castings, with a long service life;Dual motor drive, with high motor power refusing mixer jamming;The optimized design of the water spraying pipeline ensures faster and more uniform drainage. |

|

| 5 Efficient batching: Adopts a large-sized enclosure for material storage; Internal vibration type arch breaking device, smooth discharging; Double opening material door, material does not deviate; The rack adopts H-shaped steel, solid in structure. |

|

| 6 Easy Maintenance: The secondary mixer is above the finished product silo, eliminating the need for a conveyor belt to transport finished products. This design avoids the need to clean the conveyor belt of adhered finished materials, while achieving significant manpower and resource savings. The large angle discharge hopper is matched with a dual vibration motor to ensure smooth discharge:Large volume finished product silo with more storage capacity, making vehicle receiving materials more leisurely: Large size discharge door maximizing the use of carriage space. |

|

TEL: +86-4006688248

WORK: 8:00-18:00