INTRODUCTION

Series: LB series

Classification Asphalt Mixing Plant

Contact information: RTZK2003@163.com

Series: LB series

Classification Asphalt Mixing Plant

Contact information: RTZK2003@163.com

| Parameter | Unit | LB1500 | LB2000 | LB3000 | LB4000 | LB5000 |

| Original rated productivity | t/h | 120 | 160 | 240 | 320 | 400 |

| Rated mixing capacity | kg/batch | 1500 | 2000 | 3000 | 4000 | 5000 |

| Max. Productivity | t/h | 140 | 180 | 260 | 340 | 440 |

| Aggregate weighing range/accuracy(static) | % | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 |

| Powder dosing range/accuracy(static) | % | ±0.2 | ±0.2 | ±0.2 | ±0.2 | ±0.2 |

| Asphalt dosing range/accuracy(static) | % | ±0.2 | ±0.2 | ±0.2 | ±0.2 | ±0.2 |

| Oil & gravel ratio dosing range/accuracy(static) | % | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 |

| Installed power | kW | 340 | 400 | 621 | 700 | 930 |

| Fuel consumption(heavy oil)(standard condition) | kg/t | 6 | 6 | 6 | 6 | 6 |

| Gas consumption(natural gas)(standard condition) | ㎥/t | 7 | 7 | 7 | 7 | 7 |

| Standard floor space | m | 30x30 | 35x35 | 40x40 | 50x50 | 50x50 |

| Dust removal area | ㎡ | 450 | 600 | 900 | 1250 | 1500 |

| Dust discharge concentration | mg/N㎥ | <20 | <20 | <20 | <20 | <20 |

| Blackness of emitted flue gas | / | Greenman Level 1 | Greenman Level 1 | Greenman Level 1 | Greenman Level 1 | Greenman Level 1 |

| Noise in control room | dB | <70 | <70 | <70 | <70 | <70 |

| Product overview |

| The LB series asphalt mixing equipment adopts a larger mixer structure, compared to the same model on the market, it has advantages of strong equipment overproduction capacity, dosing module adopting a three-point pressure dosing module structure, and is combined with the operating system dosing and drop compensation functions, resulting in high dosing accuracy: Modular structure, negative pressure fully sealed and dust-free design the equipment has the characteristics of convenient installation and transportation, environmental protection and energy conservation, efficient and reliable production, and is widely used in the production of asphalt mixtures in surrounding asphalt pavement engineering, municipal road engineering, and high-grade pavement engineering. |

| Product characteristics |

| 1 Module design, less ground area taking, convenient installation. |

| 2 Fully sealed negative pressure design, no powder leaking, reasonable power distribution saves energy. |

| 3 Efficient thermal system structure, the burner adopts intelligent axial flow ow-pressure atomization form, and the equipment is fuel consumption is 6kg/t (finished material) under rated working conditions. |

| 4 The dosing system adopts a pressure type dosing module structure for dosing, with automatic dosing and “flying material” compensation functions, achieving high dosing accuracy. |

| 5 Mixer adopts a redundant structure design, which ensures strong mixing, the plant has strong over production capacity under the same plant model. |

| INTRODUCTIOM TO ORIGINALFUNCTIOM MODULES | |

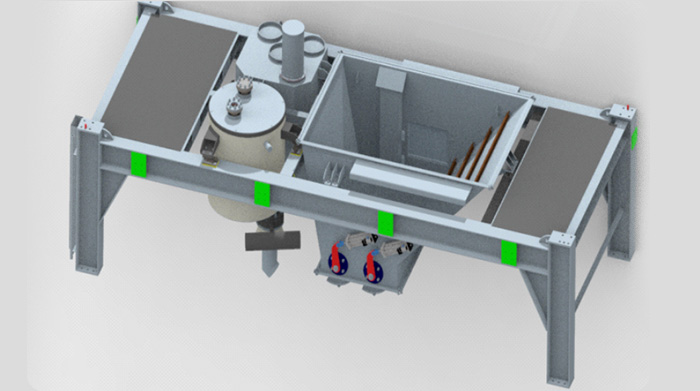

| 1 Cold material system Single silo volume is 15m³, articulated structure gives convenience for transportation. Small size material silo adopts inner vibrating structure, with big amplitude, ensuring smooth discharge. Belt conveyor feeding adopts frequency converting + door opening extent control , ensuring a stable primary grading. Equipped with material lacking alarm device. |

|

| 2 Drying system Patented blade technology, the material curtain is more uniform and has better heat absorption effect. Material containing blade feeding technology, the discharge temperature is more uniform. Large production capacity.Over-production capacity reaches 15%. Axial flow low-pressure atomization burner is with dual frequency conversion technology to control the air oil ratio, and the fuel consumption per ton of finished product is 6kg (under standard conditions). Directly driven by a direct reduction motor, with strong power and high efficiency. |

|

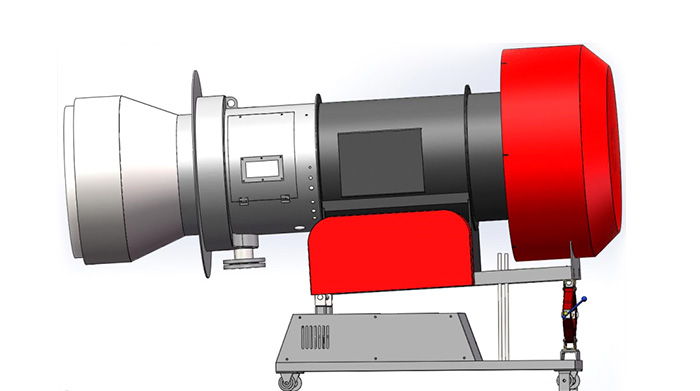

| 3 Burner The burner has a wide adjustment range and can adaptto various complex working conditions. Three stage atomizing technology, fuel is atomized into micrometer level, with fully combustion. High power pre heating device,stable fuel temperature. Remote fault diagnosis function,timely service, and ensures production reliability. Intelligent axial flow low-pressure atomization burner adopts dual frequency conversion adjustment technology with automatically adjustable air and oil distribution, ensuring a reasonable air oil ratio and sufficient combustion. The fuel consumption under rated working conditions is only 6kg/t (finished material). |

|

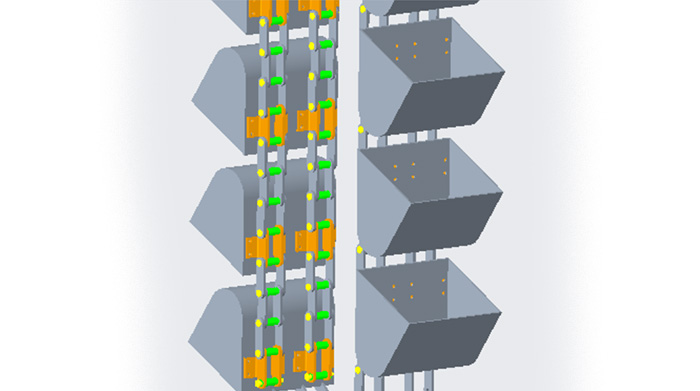

| 4 Elevating system Plate chain elevator, whose chain is not easy to stretch and is stable and reliable in use. Deceleration motor direct drive with anti reverse device. The elevator chute is equipped with a wear-resistant plate structure to improve wear resistance. |

|

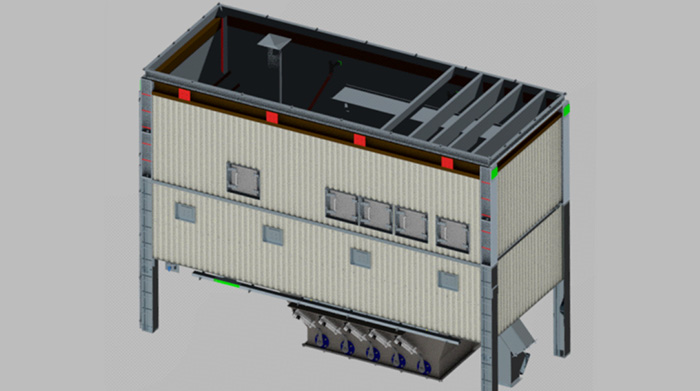

| 5 Screening system Dual-vibration motor direct drive,strong vibration effect,to achieve a maintenance free period of approximate 2000h. Large screening area and high screening efficiency. The screen mesh changing device adopts a side bolt method which is convenient for quick replacement. The shell of the vibrating screen is wrapped with insulation rock wool for insulation,noise reduction, environmental protection and energy conservation. |

|

| 6 Hot material silo system Hot aggregate silo is divided into the upper & lower silo, both adopt rock wool for insulation. Equipped with a continuous material level detection device, giving convenience for visually observing the material level of various ingredients. The silo door adopts a maintenance free structural design, large & small doors to achieve a secondary coarse & fine weighing structure, ensuring aggregate dosing accuracy. The sand silo is equipped with a temperature detection device. |

|

| 7 Dosing system Aggregate scale, asphalt scale, and filler scale are all measured using a 3-point compression dosing module. The aggregate scale adopts a coarse and fine scale structure with large and small gates, ensuring a dosing accuracy of 0.3%. The asphalt scale adopts a frequency conversion pump+secondary dosing method to ensure a dosing accuracy of 0.2%, and the dynamic secondary tracking dosing technology ensures an accuracy of 0.3% for the oil & gravel ratio. The filler scale adopts spiral conveying, pneumatic butterfly valve control, and the “fly material” control program is used to ensure dosing accuracy of 0.2%. |

|

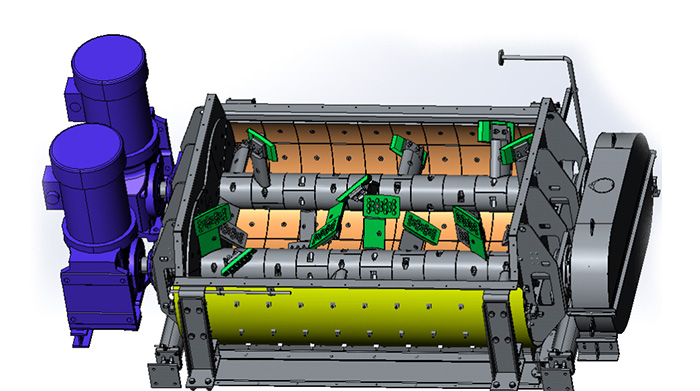

| 8 Mixing system The mixer has a large capacity and adopts power redundancy design, with sufficient power and strong power. Driven by a direct reduction motor it has strong stability. Full blade spiral stirring cloud technology, fast mixture cycling speed and strong kneading ability, to achieve the effect of rapid blending. The blades and lining plates are made of nickel chromium alloy material, with a service life of no less than100000 batches. |

|

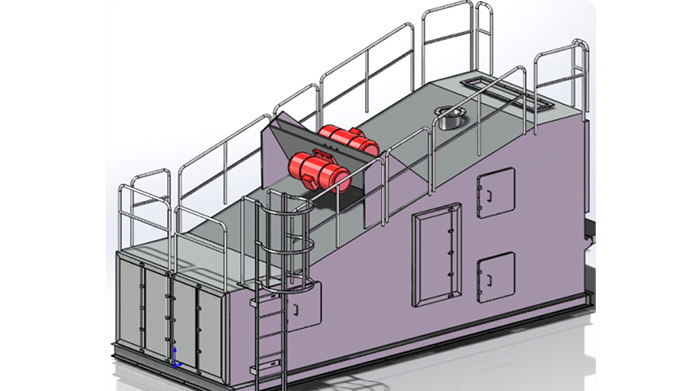

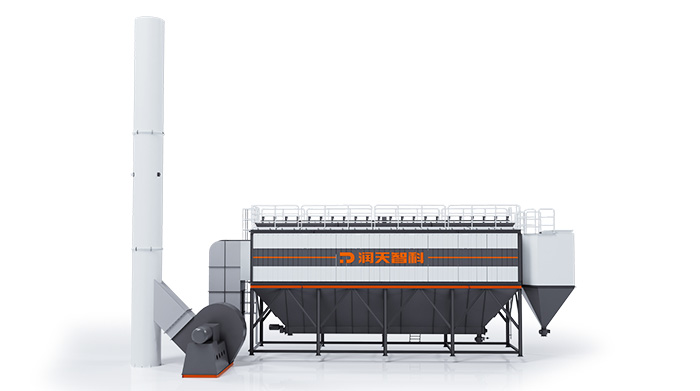

| 9 Dust collection system Adopting primary gravity dust collector and a secondary atmospheric reverse blowing bag dust collector. Emission concentration <20mg/Nm3. High-power fan ensures a sufficient air volume, which is controlled by frequency conversion to save energy and reduce noise. The flue gas pipeline is equipped with a temperature measurement device and has a high and ow temperature alarm function. |

|

| 10 Control system Equipped with 2 monitors and 2industrial control computers, when one machine malfunctions another can be used to ensure production stability. The operation interface is intuitive and clear and key currents and parameters are displayed during internship. The electrical parts adopt famous international brands, to ensure the reliability. The control program maintains functions of linkage control, safety interlock, power outage protection. Asphalt dosing has a secondary dynamic tracking dosing function; The program has “f lying material” control and automatic dosing function. With functions of online remote diagnosis, to ensure the timely service. |

|

TEL: +86-4006688248

WORK: 8:00-18:00