INTRODUCTION

Series: RZS series

Classification Asphalt Mixing Plant

Contact information: RTZK2003@163.com

Series: RZS series

Classification Asphalt Mixing Plant

Contact information: RTZK2003@163.com

| Parameter | Unit | RZS80 | RZS130 | RZS160 | RZS200 |

| Rated productivity | t/h | 80 | 130 | 160 | 200 |

| Dosing accuracy ofrecycled materials | % | ±0.3 | ±0.3 | ±0.3 | ±0.3 |

| Installed power | kW | 195 | 246 | 281 | 310 |

| Fuel consumption (heavy oil) | kg/t | 6 | 6 | 6 | 6 |

| Gas consumption (natural gas) | ㎥/t | 7 | 7 | 7 | 7 |

| Regeneration drum diameter size | m | 2.0x9 | 2.2x11 | 2.5x13 | 2.5x15 |

| Regeneration ot materiasilo capacity | ㎥ | 6 | 7 | 10 | 12 |

| Regenerated flue gas treatment | / | Secondary combustion | Secondary combustion | Secondary combustion | Secondary combustion |

| Product overview |

| The renovation and maintenance of asphalt pavement have generated a large amount of RAP in response to resource recycling and reuse, thermal regeneration mixing equipment has emerged, which first heats RAP and then fully mixes and reuses them with new asphalt mixtures. The RZS series is a factory mixed hot regeneration form which can be heated in a forward or reverse flow manner, The technology originated from Europe and can achieve a large proportion of recycled materials. The discharge temperature of recycled materials can reach 110~160degrees. The equipment is widely used in surrounding asphalt pavement engineering and municipal road engineering, especially in the production of middle and lower layer asphalt mixtures. |

| Product characteristics |

| 1 The unique drum blade design has a good effect in preventing the adhesion of recycled materials. |

| 2 The heating of recycled materials adopts a combination of thermal radiation and heat exchange, with high thermal efficiency. |

| 3 Large diameter and long drum structure, which can achieve the addition of a large proportion of recycled materials. |

| 4 Multi-points security inspection + linkage control, quick air door closing protection device + automatic shut-off unction, safe and reliable. |

| 5 The entire process of unloading recycled materials is heated and insulated with thermal oil, with good anti sticking effect. |

| 6 The main building is fully sealed with negative pressure design, without filler leakage, and the regenerated flue gas adopts secondary combustion, which is Eco-friendly. |

| INTRODUCTION TO THETHERMAL REGENERATIONFUNCTION MODULE | |

| 1 Cold feeding system Single silo volume is 12m3 adopts inner vibrating structure, with big amplitude, ensuring smooth discharge. Belt conveyor feeding adopts frequency converting + door opening extent control, ensuring a stable primary grading. Equipped with material lacking alarm device. The top of the cold material silo is equipped with a grating device to remove large pieces of material. |

|

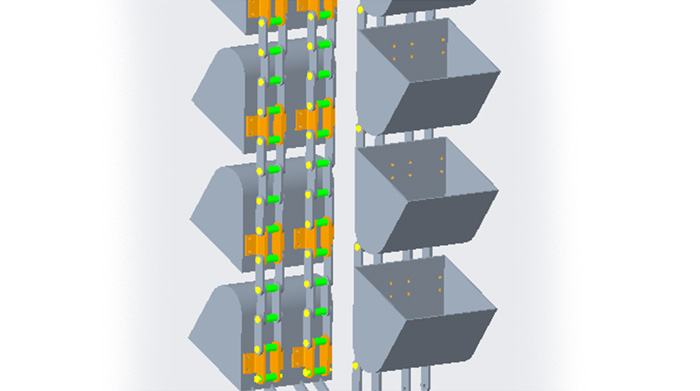

| 2 Elevating system Plate chain elevator, whose chain is not easy to stretch and is stable and reliable in use. Deceleration motor direct drive with anti reverse device. The elevator chute is equipped with a wear-resistant plate structure to improve wear resistance. |

|

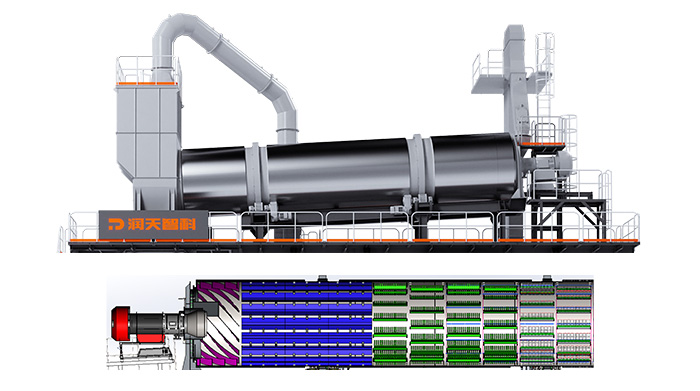

| 3 Regeneration drying drum Drum heating combines flame radiation heat and flue gas heat exchange together, sufficiently use the heat, and reduce the gas consumption. The drum adopts patented anti stick technology, with unique arrangement of internal blades. A rake type structure+swinging chain+staggered arrangement+long drum structure ensures that the regeneration drum to form a good material curtain to improve thermal efficiency. Chain swing prevents adhesion of recycled materials. Reducer equipped with directly connected motor, achieving high-efficiency driving. The discharge end is equipped with infrared temperature measurement device. |

|

| 4 Regeneration drying drum Drum heating combines flame radiation heat and flue gas heat exchange together, sufficiently use the heat, and reduce the gas consumption. The drum adopts patented anti stick technology, with unique arrangement of internal blades. A rake type structure+swinging chain+staggered arrangement+long drum structure ensures that the regeneration drum to form a good material curtain to improve thermal efficiency. Chain swing prevents adhesion of recycled materials. Reducer equipped with directly connected motor, achieving high-efficiency driving. The discharge end is equipped with infrared temperature measurement device. |

|

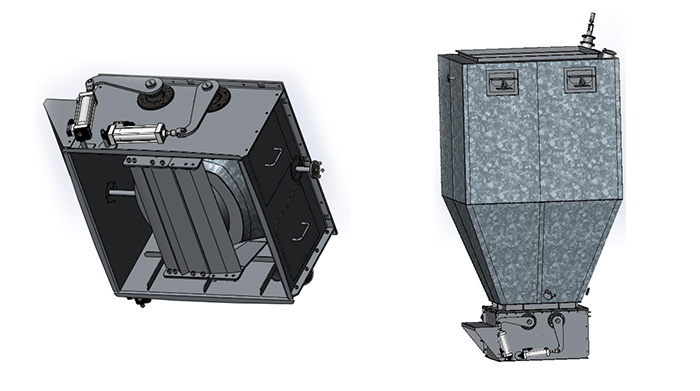

| 5 Recycled hot material silo The hot material silo adopts a large capacity structure with a large angle wall, which is equipped with a thermal oil heating device to ensure smooth and non adhesive discharge of recycled materials. Hot material silo adopts small & big door combined structure, with the function of accurate dosing. |

|

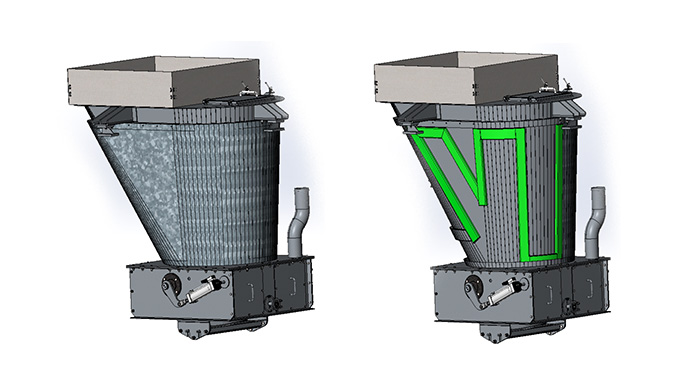

| 6 Recycled material dosing silo & chute The dosing silo adopts a 3 - point pressure dosing module, ensuring accurate and stable dosing. The silo wall is equipped with a thermal oil heating device. The silo is equipped with wear-resistant plates to ensure wear resistance. Recycled material chute adopts a large sectioned area & arge dip angle structure, equipped with heat transfer oil to maintain the temperature, anti-wear liner is set to the chute inner chute to resist the abrasion. |

|

| 7 Recycled flue gas treatment The regenerated flue gas is treated with secondary combustion in the original drum, which is environmentally friendly and energy-saving. The blades of the induced draft fan are treated with anti adhesion, which is not easy to be adhered by material. The discharge box adopts a large cross-section structure with the function of settling fine particles. |

|

TEL: +86-4006688248

WORK: 8:00-18:00